Assessing brick production

Practical Action

You can tell a lot about bricks by soaking them in cold water for 48 hours. If you weigh bricks

before and after soaking, you can calculate the percentage of water they absorb. A good brick

shouldn't absorb more than 15% of its dry mass. If bricks are too absorbent they suck

moisture out of mortar and weaken the bond. You may find the brick dissolves altogether. In

this case, it's definitely underfired - and dangerous to use in any building. The presence of

lime may also be detected by soaking bricks. If lime is present as lumps, it may expand and

cause fractures, exposing powdery white deposits.

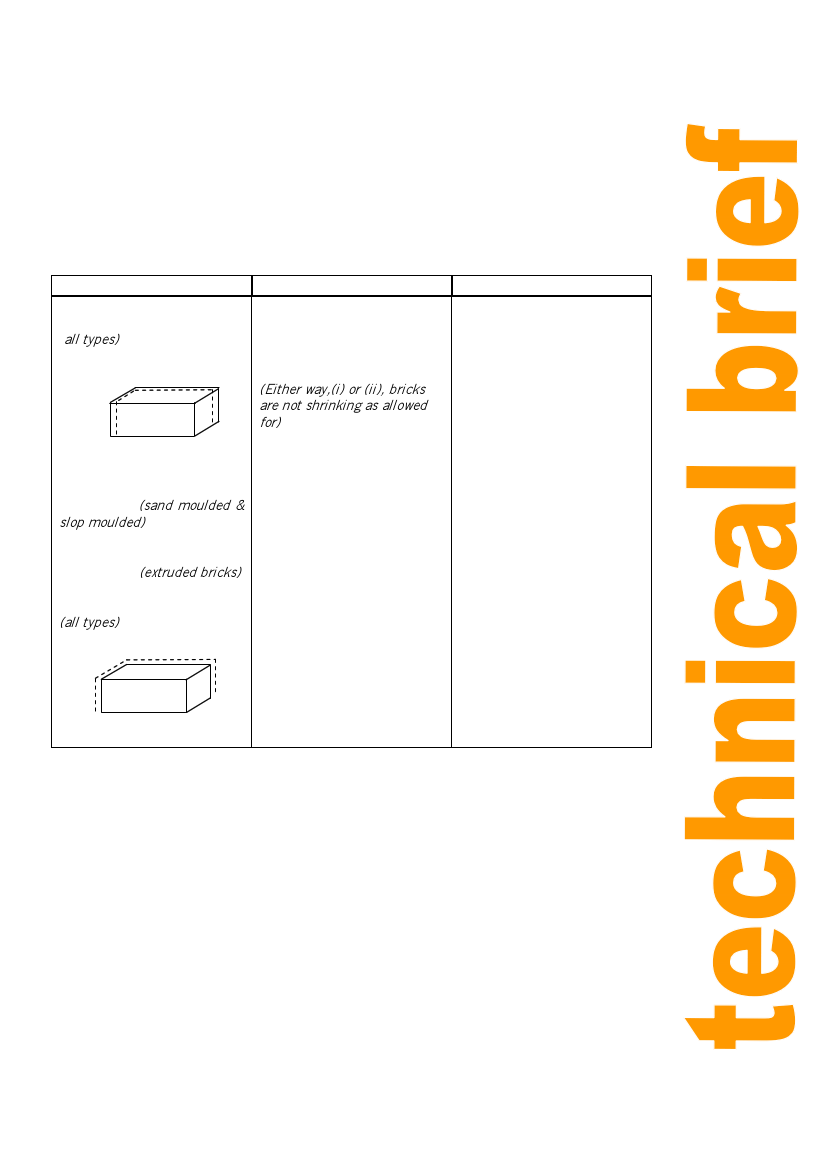

BRICK PROBLEM

1. SIZE

(a) Too big in all dimensions

(all types)

PROBABLE REASON

(i) Too many coarse particles

in raw material

POSSIBLE SOLUTION

(i) Sieve out coarse material or

crush soil before moulding

(ii)Underfired

(Either way,(i) or (ii), bricks

are not shrinking as allowed

for)

(iii) Mould or extrusion die is

too big - worn?

(ii) Increase firing temperature

&/or time (increase fuel?)

(iii) Replace

(b) Too thin (sand moulded & Squashed in handling -

slop moulded)

probably when laid to dry on

edge

More care handling bricks &

try moulding a little drier

(c) Too thick (extruded bricks) Cutting wires set wrongly

Adjust settings

(d) Too small in all dimension

(all types)

(i) Die or mould too small

(ii) Too high clay content -

excessive drying shrinkage

(i) Change

(ii) Add sand

(iii) Overburned - excessive

firing shrinkage - may affect

bricks only in hot-spots in kiln

(iii) Use less fuel. Try to avoid

hot-spots by distributing fuel

differently

2